ProfiTurn H Crankshaft Turning

Horizontal lathes for the highest precision and performance

ProfiTurn H crankshaft lathes at a glance

WaldrichSiegen horizontal turning lathes, ProfiTurn H, are the ideal machine tools for economic and efficient machining of large crankshafts for 2-stroke diesel engines. Due to their rigid design and the hydrostatic guideways of both turning carriage/top rest (for machining of the main bearings), as well as, for the pin turner, the WaldrichSiegen crankshaft lathes guarantee high-precision finish machining of crankshafts with excellent surface quality.

During design of WaldrichSiegen crankshaft lathes, life cycle costs have been consistently taken into account. The machines impress with their easy service and maintenance, energy efficiency and high quality of all machine components.

Machine Concept

Highest productivity and efficiency

WaldrichSiegen attaches great importance to a rigid design and maximum stiffness of the overall machine structure. In principle, crankshaft machines of the ProfiTurn H series are equipped with hydrostatic guideways in all linear axes providing for high wear-free operation, as well as, excellent damping characteristics.

Productivity and efficiency of these crankshaft lathes can be increased with the so-called twin or double carriage concept developed by WaldrichSiegen. Approximately 70 % of the total processing time of a crankshaft is needed for machining the main bearings. In the twin concept the two workpiece sides of a twin crankshaft lathe make joint usage of a pin turner and thus provide for maximum machine utilization at reduced investment costs.

Technology tailored to your needs

+ Machine beds

WaldrichSiegen machine beds – made of cast iron – are available in two-section design. Their ribbed structure ensures maximum bending and torsional stiffness, as well as, an optimal load introduction into the foundation. Precise guidance of the bed slide and exact positioning of steadies, tailstock and peripheral equipment are completely guaranteed.

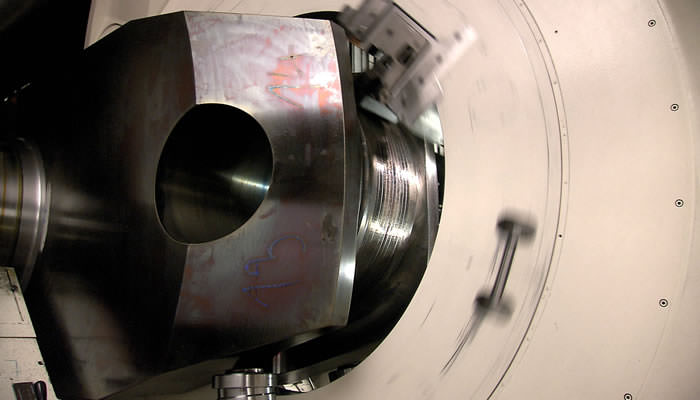

+ Headstock and faceplate

The headstock design is crucial for the achievement of the highest run-out accuracies and maximum performance. Therefore, it is cast in one piece and additionally ribbed. The axial and radial bearing placed close to the faceplate provides for the highest precision. Made of cast iron, the faceplate can accommodate workpiece weights of up to 300 tons. Recent drive systems like the Master-Slave-drive, for example, enable the optimal machining of crankshafts with the highest precision and performance.

+ Hydrostatic guideways and drives

An electrically pre-loaded Master-Slave double drive is used for longitudinal drive. Traverse adjustment of the upper carriage and pin turner is carried out via a pre-loaded ballscrew.

+ Upper carriage with tool carriers

WaldrichSiegen turning lathes meet the requirements for highest stiffness and accuracy by means of an optimized upper carriage made of cast iron which can be adapted to the needed machining tasks. A suitable combination of tool carriers in different widths allows the machine to be adjusted to the needed customer requests.

+ Pin turner

The pin turner, specially designed by WaldrichSiegen, allows for machining of crank pins of large 2-stroke-crankshafts with diameters of up to 1.300 mm and a width of up to 220 mm. The pin turning device is hydrostatically guided. While the turning tool is adjusted mechanically without involvement of a slip ring, the highest accuracies and easy maintenance are ensured.

+ Control technology

Latest state-of-the-art control technology made by well-known manufacturers ensures maximum reliability and ease of use. The integrated diagnostic system, developed by WaldrichSiegen, monitors all relevant machine parameters, thus keeping the machine operators permanently informed on the current machine status and helping them in troubleshooting, this reduces downtime to a minimum.

Options

A comprehensive range of accessories are available for the ProfiTurn H crankshaft lathes:

- Hydrodynamic steady rests

- Centering device

- Tool and workpiece measuring systems

- Cheek distance deviation measuring for fast alignment of workpiece

- Coolant systems

- Further accessories available

Performance data

Our horizontal lathes are designed for superior performance in all applications. Main characteristics of the ProfiTurn H are:

- Power: up to 500 kW

- Torque: up to 400,000 Nm

- Workpiece weight: up to 500 t

- Workpiece length: up to 30,000 mm

- Workpiece diameter: up to 7,000 mm

- Concentricity: ≥ 5 µm

ProfiTurn H Crankshaft Turning