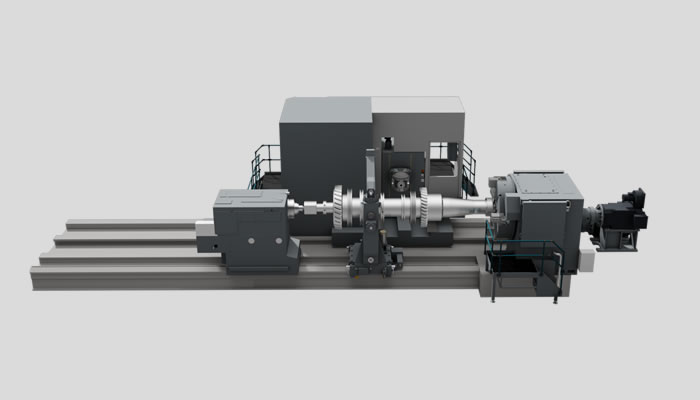

ProfiTurn M: New Mill-turning Machine Made by WaldrichSiegen

Multi-talent: various machining technologies on a single machine

WaldrichSiegen has expanded its product range with a new mill-turning machine. The ProfiTurn M has been specifically designed for the complete machining of complex, rotationally symmetric workpieces that are run through several processing stages. Both turning and milling units, as well as boring and grinding units can be attached to the Masterhead interface located at the milling tower. The result is highest efficiency, as all machining stages can be performed on a single machine and multiple set-ups, which are both elaborate and costly, are reduced.

Whether turbine or generator rotors or heavy forged parts – the ProfiTurn M has been developed for the precise and efficient machining of demanding workpieces with a diameter of up to 4.2 m, a length of 25 m and weights between 20 and 250 t. The extremely rigid box-in-box construction of the milling tower guarantees highest stability, even when great cutting forces are involved. The completely encased machine operates precisely and wear-freely thanks to the hydrostatic guides both in the carriage and the bed. Depending on the customer’s requirements, either a high-performance boring and milling spindle or a ram is integrated in the traversing column. A tool and unit changer can be added for fully automatic operation of the machine.

WaldrichSiegen continues to round off its product portfolio with the ProfiTurn M. While the tried-and-tested horizontal lathe ProfiTurn H covers more simple mill-turning tasks, the ProfiTurn M is now the ideal solution for all the more complex mill-turning operations.

The Highlights of the ProfiTurn M at a Glance:

- Extremely rigid box-in-box design

- Powerful main spindle

- Hydrostatic guides in the carriage and bed

- Workpiece support (steady rests) of all types

- Full room enclosure

- Operator and maintenance-friendly concept

- Energy efficient design of the machine

- Comprehensive equipment

Technical Data

- Workpiece diameter: 1 - 4.2 m

- Distance between the centers, max.: 25 m

- Workpiece weight, max.: 250 t

- Power at the headstock, max.: 310 kW

- Milling power, max.: 80 kW

- Torque, max.: 7,000 Nm