Trusting cooperation

Tosyali Toyo orders complete roll shop

Investing in a large machine tool from WaldrichSiegen is an investment for the future, which continues paying off for many decades. Due to the high quality of each single component and minimal wear characteristics, the machines guarantee the utmost machining qualities and reliability for decades to come. Additionally, the maintainability of the machines as well as fast and reliable service are the basis for a long-lasting, stellar cooperation.

Dr. Stephan Witt, President at WaldrichSiegen, emphasizes: "Customers, who once made a decision for WaldrichSiegen, will come back again. We maintain many long-lasting partnerships because we guarantee reliable quality and low life cycle costs for the customer.

"Eight years ago, WaldrichSiegen delivered a texturing machine to the Japanese Toyo Kohan Ltd., manufacturer of steel sheet products. As a joint venture with the Turkish Tosyali holding, "Tosyali Toyo Steel", the Japanese company is currently building a new cold rolling mill in Osmaniye, Turkey. The cooperation with WaldrichSiegen convinced the customer – Tosyali Toyo Steel placed a new major order with WaldrichSiegen: a complete roll shop.

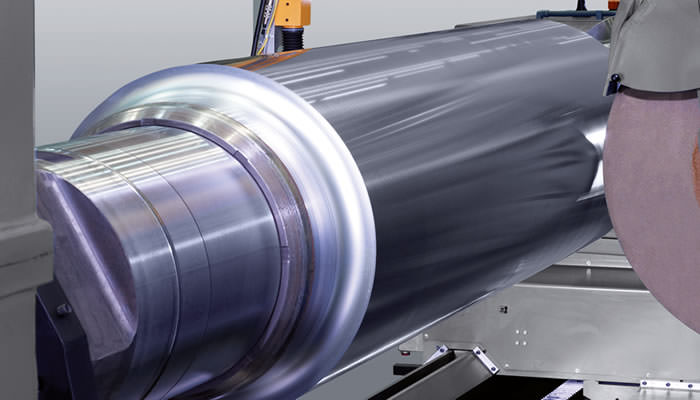

One reason why WaldrichSiegen was awarded the order was the comprehensive know-how of WaldrichSiegen in the field of texturing. Again, the customer opted for a double row texturing machine ProfiTex 60. The ProfiTex machine does not only achieve exactly repeatable surface roughness but also extended roll running times up to 300 % in the mill stand.

In addition to that, WaldrichSiegen will deliver four ProfiGrind roll grinders for the new cold rolling mill: one ProfiGrind 2500 for machining backup and work rolls, two ProfiGrind 600 K for work rolls and one ProfiGrind 300 K for rubber rolls. The machines are designed for the high demands of the cold rolling mill: The manufactured products are used e.g. for food packaging, the automobile industry, household appliances or computers. They require the utmost surface qualities at the roll. The new WaldrichSiegen roll shop will contribute to achieving such high standards. The effciency of the roll shop is assured by the Roll Shop Management System (RSMS) – also part of the scope of supply.

The RSMS collects and evaluates all information coming from the roll shop, which is completely planned by WaldrichSiegen. The advantages are very few downtimes and bottlenecks. With additional WaldrichSiegen roll shop and roll handling devices, like chock tilter and dechockers, the customer is optimally equipped. However, the total WaldrichSiegen package comprises even more. Jörg Naumann, President Sales, explains: "WaldrichSiegen does not only deliver state of the art equipment but provides its customers also with its service package: Processing, delivering on time, commissioning, after-sales-service – Tosyali Toyo Steel knows that they can rely on us in all aspects."