K-Series

Comprehensive machining with utmost precision

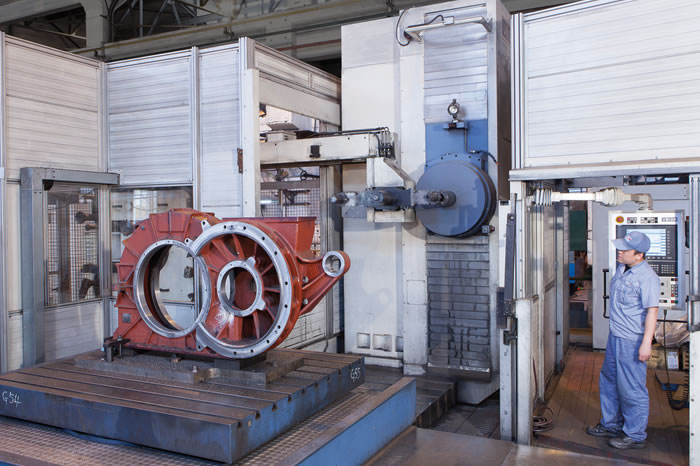

The horizontal boring mills of the K-series in planer type allow an efficient and precise complete machining of large, prismatic workpieces. Due to the modular design and a wide scope of accessories, they can be precisely tailored according to the requirements of your workpieces.

Classification

- K Planer type

- C With automatic tool changer

- U With permanently integrated facing head

- R With ram

- G High-precision boring mill

Boring spindle diameters available

- 130, 150, 162 mm

The advantages at a glance

The planer type of the boring mill allows flexible complete machining of the workpiece without conversion. The workpiece change unit and the high level of automation guarantee minimal downtimes. The workpiece change itself can be realized either by means of a pallet changer or with an integrated table design.

Flexible and precisely designed

All linear axes have precision roller guides that guarantee a perfect machining result, just as the longitudinal compensation of the boring spindle and ram, with engine speeds of up to 5,000 rpm.

Optionally, the machines are available with hydrostatic guideways, permanently integrated NC facing head or as high-precision boring mills KG.

The K-series design

The K-series is characterized by its compact and robust design: the ribbed column, cast in one single piece, guarantees the highest stiffness. The machine beds, arranged in T-form, are generously dimensioned. Preloaded precision ball screws and linear compact roller guides allow for the highest machining accuracies. The hydraulic segment clamping of the table permits a high cutting performance.

By manufacturing all core components either in-house or within the companies of the HerkulesGroup, our experts can guarantee the highest quality. The K-series can optionally be equipped with a hydrostatic ram including an additional infeed axis.

Options

Thanks to many options, the machines of the K-series can be perfectly tailored to the requirements of your production:

Automatic tool changer

Depending on the number of required tools, you can choose between different automatic tool changers:

- Travelling tool magazine with max. 60 tools

- Magazine with max. 120 tools and linear feeder

- Arena magazine with max. 176 tools

Pick-up station

Milling heads are automatically changed by a shuttle located under the tool changer.

CNC controls

Four variants are available: Siemens 840 D sl, Heidenhain iTNC 530, Heidenhain TNC 640 and Fanuc 31iB.

Twin-table design

This stable workpiece change unit can move loads of up to 60,000 kg.

NC-controlled facing head

The saddle can be integrated permanently in the head stock. The boring spindle can be used without removal of the facing head.

Precision boring mill

The precision boring mill KG achieves the highest precision during boring, using an optimal thermal management system and many detail optimizations.

Comprehensive accessories

You can choose from a broad spectrum of milling attachments as well as rotary, traversing and tilting tables.

| Technical data | K/KC 130 | K S/KC S 130 | K/KC/KCU 150 | KR/KCR 150 | |

| Boring spindle | |||||

| Diameter | mm | 130 | 130/150 | 150/162 | 150 / 162 |

| Drive power, max. (S6) | kW | 67 | 73 | 73 | 84 |

| Torque, max. (S6) | Nm | 2,179 | 3,312 | 3,170 | 5,800 |

| Engine speed range, stepless, max. | min-1 | 5...5,000 | 5...4,000 | 5...3,500 | 5...3,500 |

| Traverses | |||||

| X-axis | mm | 2,500...6,000 | 2,500...6,000 | 3,200...6,000 | 3,200...6,000 |

| Y-axis | mm | 2,000...3,500 | 2,000...3,500 | 2,000...3,500 | 2,500...4,000 |

| Z-axis | mm | 1,000...2,100 | 1,500...3,200 | 1,500...3,000 | 1,500...3,500 |

| W-axis | mm | 750 | 800 | 750 | 750/1,000 |

| Feed / Rapid traverses | |||||

| Feed range of all axes | mm/min | 1...15,000 | 1...15,000 | 1...15,000 | 1...15,000 |

| Rapid traverse of the linear axes, max. | mm/min | 22,500 | 28,000 | 22,500 | 25,000 |

| Technical data | K/KC 130 | |

| Boring spindle | ||

| Diameter | mm | 130 |

| Drive power, max. (S6) | kW | 67 |

| Torque, max. (S6) | Nm | 2,179 |

| Engine speed range, stepless, max. | min-1 | 5...5,000 |

| Traverses | ||

| X-axis | mm | 2,500...6,000 |

| Y-axis | mm | 2,000...3,500 |

| Z-axis | mm | 1,000...2,100 |

| W-axis | mm | 750 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 1...15,000 |

| Rapid traverse of the linear axes, max. | mm/min | 22,500 |

| Technical data | K S/KC S 130 | |

| Boring spindle | ||

| Diameter | mm | 130/150 |

| Drive power, max. (S6) | kW | 73 |

| Torque, max. (S6) | Nm | 3,312 |

| Engine speed range, stepless, max. | min-1 | 5...4,000 |

| Traverses | ||

| X-axis | mm | 2,500...6,000 |

| Y-axis | mm | 2,000...3,500 |

| Z-axis | mm | 1,500...3,200 |

| W-axis | mm | 800 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 1...15,000 |

| Rapid traverse of the linear axes, max. | mm/min | 28,000 |

| Technical data | K/KC/KCU 150 | |

| Boring spindle | ||

| Diameter | mm | 150/162 |

| Drive power, max. (S6) | kW | 73 |

| Torque, max. (S6) | Nm | 3,170 |

| Engine speed range, stepless, max. | min-1 | 5...3,500 |

| Traverses | ||

| X-axis | mm | 3,200...6,000 |

| Y-axis | mm | 2,000...3,500 |

| Z-axis | mm | 1,500...3,000 |

| W-axis | mm | 750 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 1...15,000 |

| Rapid traverse of the linear axes, max. | mm/min | 22,500 |

| Technical data | KR/KCR 150 | |

| Boring spindle | ||

| Diameter | mm | 150 / 162 |

| Drive power, max. (S6) | kW | 84 |

| Torque, max. (S6) | Nm | 5,800 |

| Engine speed range, stepless, max. | min-1 | 5...3,500 |

| Traverses | ||

| X-axis | mm | 3,200...6,000 |

| Y-axis | mm | 2,500...4,000 |

| Z-axis | mm | 1,500...3,500 |

| W-axis | mm | 750/1,000 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 1...15,000 |

| Rapid traverse of the linear axes, max. | mm/min | 25,000 |

- K Planer type

- C With automatic tool changer

- U With permanently integrated facing head

- R With ram

Product film