Products From

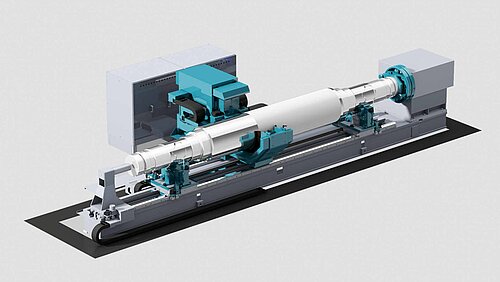

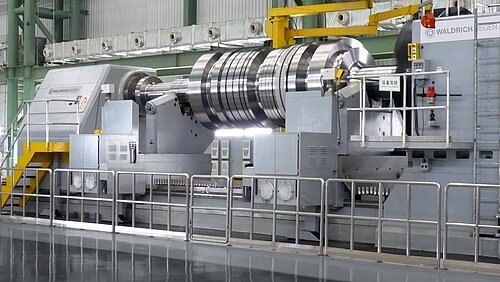

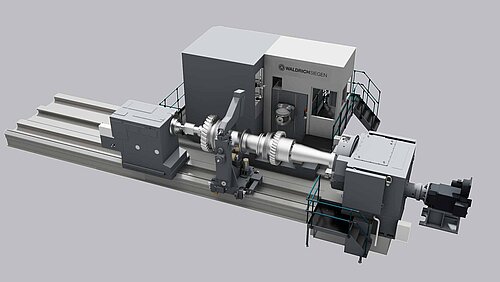

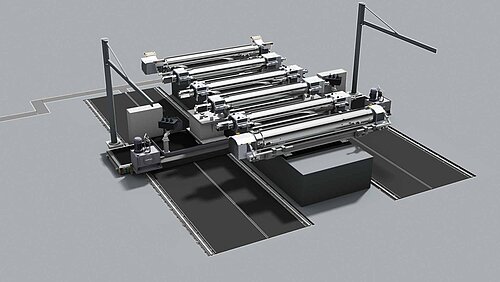

WaldrichSiegen

Your Partner for Challenging Projects

WaldrichSiegen is the world's leading supplier of heavy-duty machine tools in the field of milling, turning, grinding, texturing and boring. When developing our products, we strive for maximum precision, efficiency and reliability - performance characteristics that WaldrichSiegen guarantees through sophisticated design down to the last detail, a high level of vertical integration and an absolute commitment to innovation.