T-Series

Effective multi-side machining for medium sizes

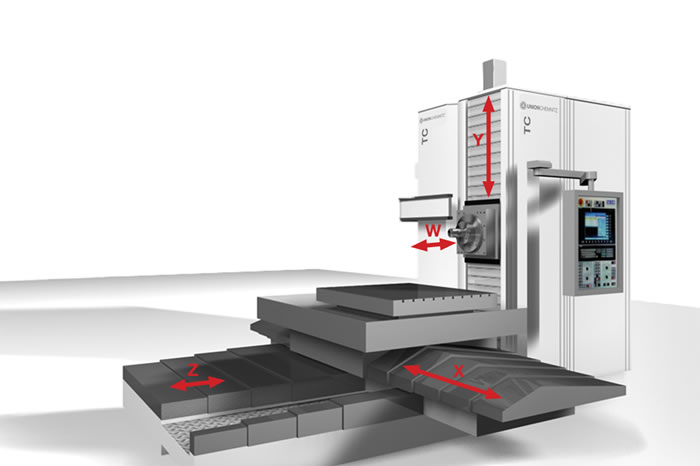

The table-type horizontal boring mills of the T-series are perfectly designed for the effective multi-side machining of medium-sized workpieces. The machines can be tailored to individual customer requirements with a wide range of options and special equipment.

Classification

- T Table type

- C With automatic tool changer

- U With permanently integrated facing head

Boring spindle diameters available

- 130, 150, 162 mm

Advantages at a glance

The T-series machines are exceptionally robust thanks to their wide machine beds with four guideways for longitudinal traverse and the strongly ribbed, stiff column.

The compact precision roller guides and the longitudinal compensation of the boring spindle permit the highest machining accuracies. The machine offers a drive power up to 73 kW and spindle speeds of up to 4,000 rpm.

A wide range of accessories contributes to the overall flexibility during all steps of the manufacturing process.

Technology

The robust design of the wide machine bed with four guideways and a cast-iron column provides a high static stiffness and thus allows for the highest precision. The column, ribbed inside, damps vibrations and prevents flexing.

To guarantee the highest quality, headstocks and spindles are manufactured in-house at the companies of the HerkulesGroup. The precision spindle bearing with permanent lubrication, a two-step gearbox with circulation system lubrication and a cooling unit for consistent temperature result in low wear and a high machining quality.

An axial-radial cylinder roller bearing guarantees the precise rotation of the workpiece on the rotary clamping table, with zero backlash. A high cutting performance is achieved by hydraulic segment clamping.

The machines of the T-series feature a comprehensive range of options for adaption to different applications:

Automatic tool changer

Up to 120 tools can be changed automatically, including the NC-controlled facing head.

Compact coolant unit

The external coolant is fed in at the headstock with 80 l / 8 bar, the internal coolant is fed in through the middle of the boring spindle, or optionally through the milling head spindle, with up to 90 bar.

NC-controlled facing head

A NC-controlled facing head can be permanently integrated in the headstock. The boring spindle can be used without removing the facing head.

Process optimization

The optimization of each manufacturing step is achieved by monitoring the service life and torque, fracture control and automatic identification of the tools, recording the operating data, and a wireless touchprobe.

Work area housing / CE-based operation

A panel that swivels into the work area, optionally in desk design, a complete housing, optionally with vacuum exhaust system, and a table housing provide utmost safety.

Automatic workpiece changer

A standard pallet changer with up to four stations changes the workpieces automatically.

CNC controls

Four variants are available: Siemens 840 D sl, Heidenhain iTNC 530, Heidenhain TNC 640 and Fanuc 31iB.

Comprehensive equipment

You can choose from a wide spectrum of milling heads as well as various rotary, traversing and tilting tables.

| Technical data | T/TC 130 | T/TC/TCU 150 | |

| Boring spindle | |||

| Diameter | mm | 130 | 150/162 |

| Drive power, max. (S6) | kW | 46 | 73 |

| Torque, max. (S6) | Nm | 2,179 | 3,170 |

| Engine speed range, stepless, max. | min-1 | 5...4,000 | 5...3,500 |

| Traverses | |||

| X-axis | mm | 2,000 / 2,500 | 2,000 / 2,500 |

| Y-axis | mm | 2,000 / 2,500 | 2,000 / 2,500 |

| Z-axis | mm | 1,500 | 1,500 |

| W-axis | mm | 750 | 750 |

| Feed / Rapid traverses | |||

| Feed range of all axes | mm/min | 1...6,000 | 1...6,000 |

| Rapid traverse of the linear axes, max. | mm/min | 15,000 | 15,000 |

| Technical data | T/TC 130 | |

| Boring spindle | ||

| Diameter | mm | 130 |

| Drive power, max. (S6) | kW | 46 |

| Torque, max. (S6) | Nm | 2,179 |

| Engine speed range, stepless, max. | min-1 | 5...4,000 |

| Traverses | ||

| X-axis | mm | 2,000 / 2,500 |

| Y-axis | mm | 2,000 / 2,500 |

| Z-axis | mm | 1,500 |

| W-axis | mm | 750 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 1...6,000 |

| Rapid traverse of the linear axes, max. | mm/min | 15,000 |

| Technical data | T/TC/TCU 150 | |

| Boring spindle | ||

| Diameter | mm | 150/162 |

| Drive power, max. (S6) | kW | 73 |

| Torque, max. (S6) | Nm | 3,170 |

| Engine speed range, stepless, max. | min-1 | 5...3,500 |

| Traverses | ||

| X-axis | mm | 2,000 / 2,500 |

| Y-axis | mm | 2,000 / 2,500 |

| Z-axis | mm | 1,500 |

| W-axis | mm | 750 |

| Feed / Rapid traverses | ||

| Feed range of all axes | mm/min | 1...6,000 |

| Rapid traverse of the linear axes, max. | mm/min | 15,000 |

- T Table type

- C With automatic tool changer

- U With permanently integrated facing head

Product film