Roll Shop From WaldrichSiegen

Everything From One Single Source

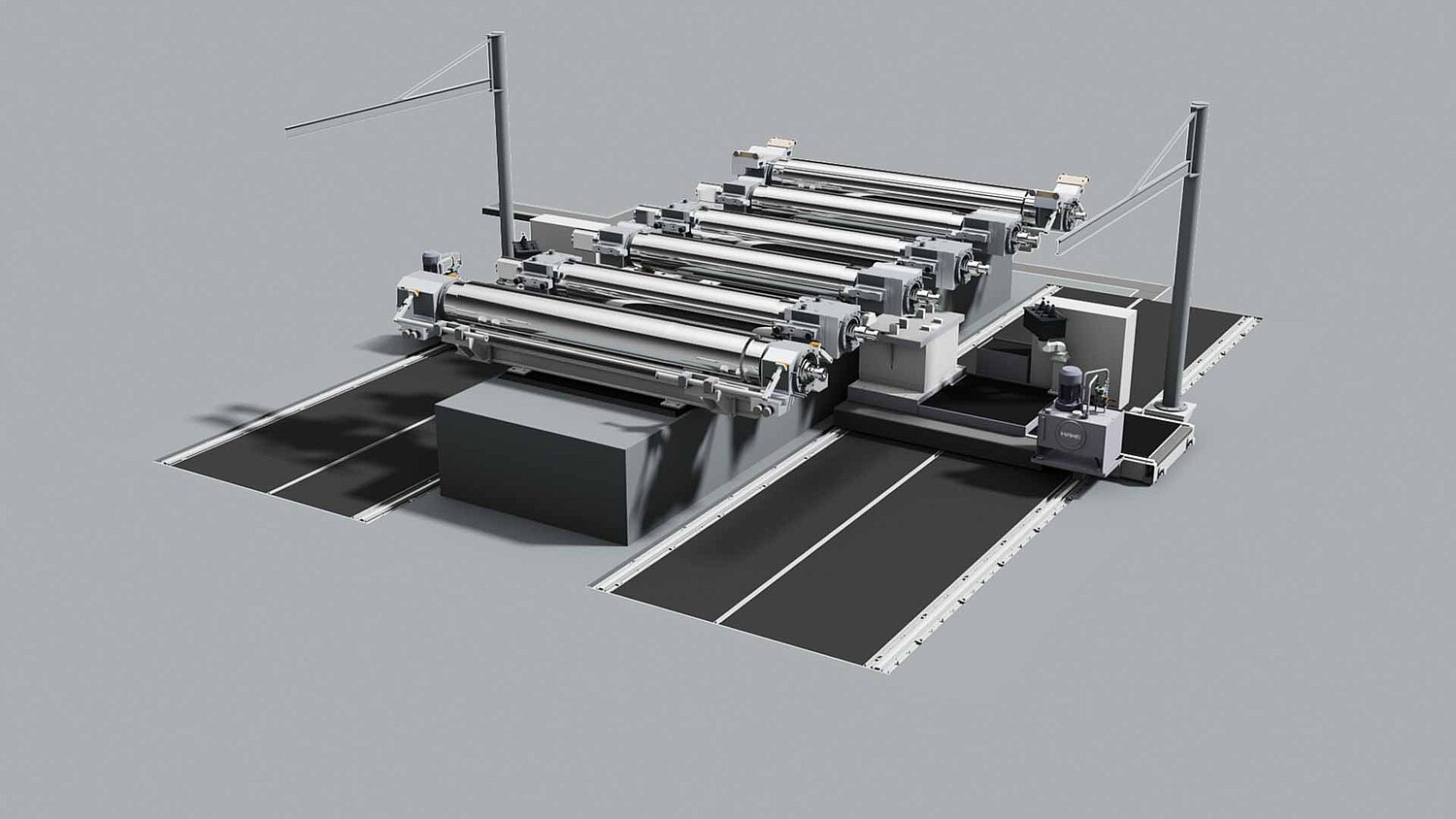

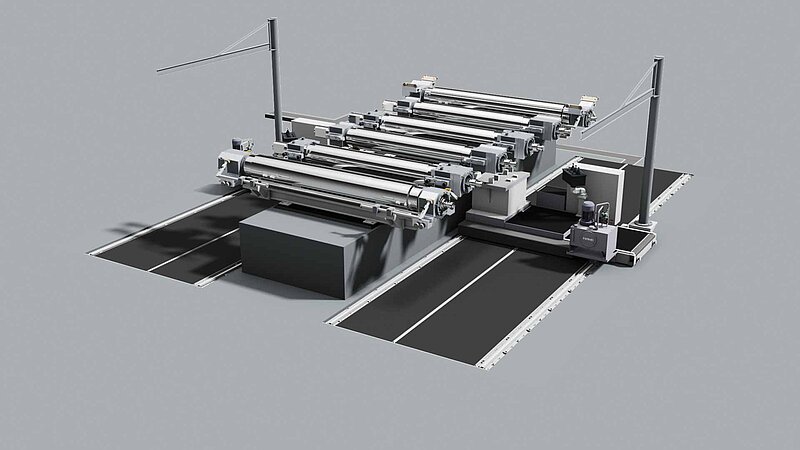

Planning, designing, manufacturing and installation from one single source – if you need more than a highly productive stand-alone roll grinder and EDT machine, WaldrichSiegen is your partner for the supply of a complete roll shop.

The simulation-based analysis calculates and evaluates all roll movements through all stations of the roll shop. This way, we can rule out any potential bottlenecks in advance and guarantee the ideal choice of machines as well as staff and set-up requirements.

Components

Individual Customer Orientation

In addition to the roll processing machines, the WaldrichSiegen product portfolio includes a wide range of accessories and components for complete roll shops:

- Loaders for transporting rollers and loading and unloading the machines in the roll store

- Pulling machines for chocks of work rolls, intermediate rolls and back-up rolls

- Combination stripping machines for different roll types

- Tilting chairs for the inspection, assembly and disassembly of chocks

- Transport trolleys for rollers

- Racks for all types of rollers

- Cooling and cleaning systems

- Knife grinding machines

Industries

The Right Solution for Every Industry

WaldrichSiegen is your competent partner for innovative, customer-specific machine solutions. We design customized machines according to the latest state of the art and the highest quality standards for all industries.

Machine Technology

Planning, Designing, Manufacturing and Installation From One Single Source

Maximum automation, perfect planning and efficiency WaldrichSiegen sets the stage for realizing the perfect conditions for your roll store in every detail.

Technology