The Evolution of the ProfiMill Series

Compact Design for Heavy-Duty Machining and High-Speed Finishing

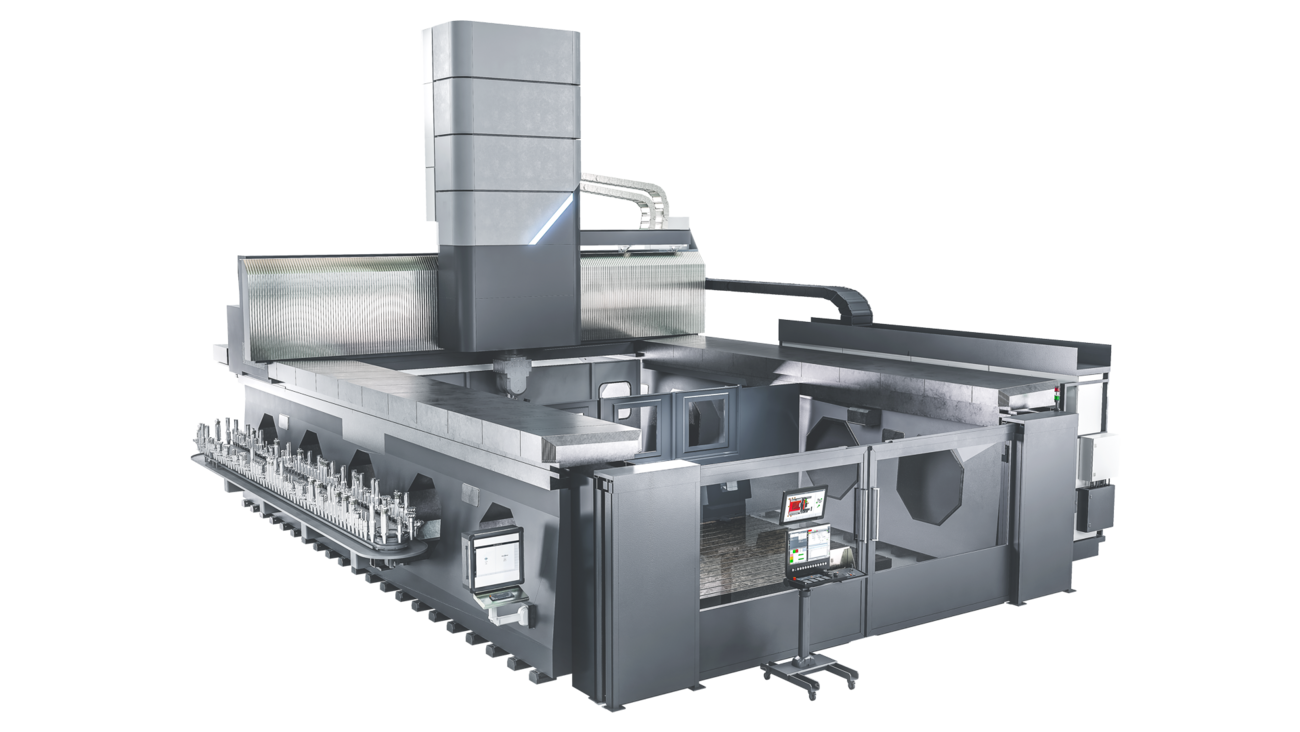

With the ProfiMill evo, WaldrichSiegen has developed a flexible yet highly productive high-gantry portal milling machine that combines the proven technology of the ProfiMill series with Herkules Monolith™ technology thus ensuring a rigid machine base that enables flexible, foundation-free installation.

The ProfiMill evo impresses with its compact and slim design. During the development process emphasis was placed on short commissioning times and flexible installation.

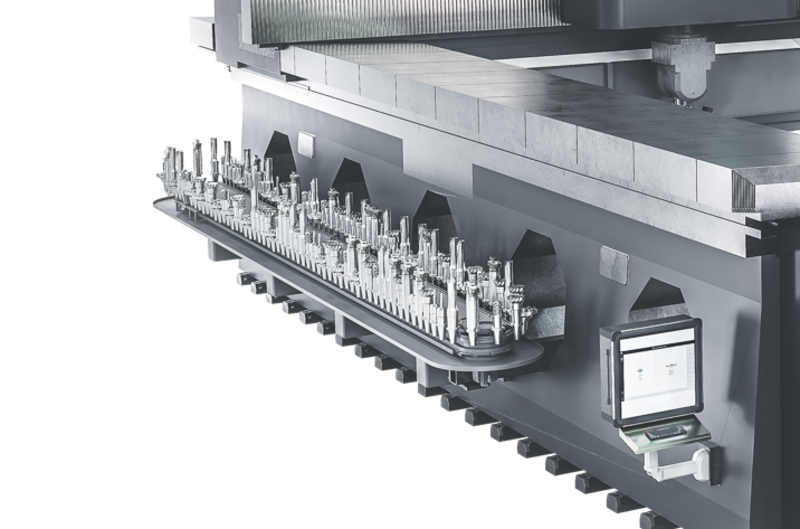

Technical Data

For Highest Quality and Efficiency

Speed

up to 6,000 min-1

Torque

2,750 Nm max

Clearance width

5,000 mm

Clearance height

2,000 mm

Travel Distance

X-axis 7,500 mm

Y-axis 5,000 mm

Z-axis 2,000 mm

C-axis +/- 190°

Travel Speeds

X-axis 40,000 mm/min

Y-axis 40,000 mm/min

Z-axis 30,000 mm/min

C-axis 10 rpm

Drive

80 kW

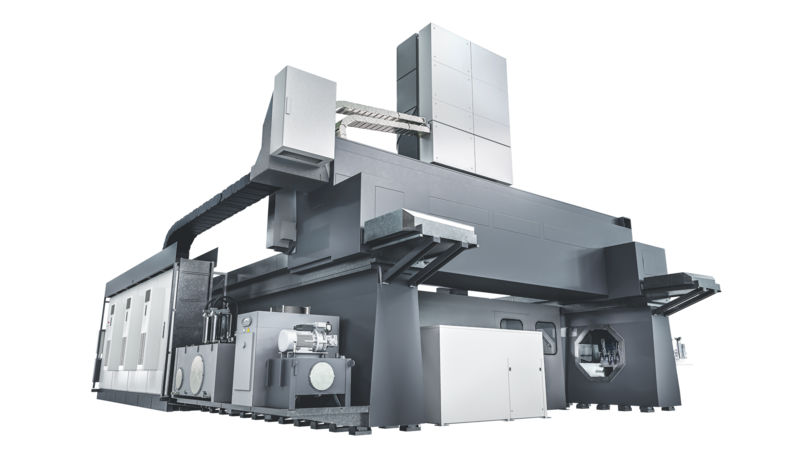

Developed for Heavy Roughing and Highly Dynamic Finishing Operations

Designed for Highest Stability

and Reliability

- The rigid cast beds enable foundation-free installation forming the side walls of the working area at the same time

- Excellent mass distribution for optimum dynamic behavior

Maximum Performance

Without Compromise

The ProfiMill evo is characterized by its compact dimensions and flexible installation options without compromising on performance. Thanks to the hydrostatic guidance of the machine axes, the ProfiMill evo achieves highest precision and maximum cutting rates at the same time.

The ProfiMill evo is designed for both finishing and heavy-duty machining.

- Small footprint required

- The machine achieves its quality without expensive and time-consuming foundation work

- Flexible installation: machine can be relocated if required

- Short delivery time due to modular design

- Short assembly times

- Long service life thanks to wear-free hydrostatic guideways

Saving Resources with Durable Products

Sustainable Machine Tool Manufacturing in Germany

Comprehensive resource-saving technologies for reducing energy consumption and emissions make the ProfiMill evo not only efficient, but also durable and sustainable

- Components with high energy efficiency such as LED lighting and frequency-controlled pumps and further units.

- The high cutting performance results in a reduced energy requirement per component thanks to short processing times.

- Strategies for energy recovery are used (e.g. combined heat and energy system, heat pumps etc.).

- The great variability of the ProfiMill evo leads to efficient use and applicability of the machine.

- We provide support for our machines even after decades, so that they can be used sustainably in the long term through modernization and overhaul.

WaldrichSiegen is a partner of the VDMA's Blue Competence sustainability initiative and is committed to complying with the twelve corresponding guidelines.

Industry 4.0

Digital Performance

and Connectivity

The ProfiMill evo is supplied with the new Siemens SINUMERIK ONE control. This provides the basis for a complete digital process chain. Modern software solutions increase productivity, prevent rejects due to production errors and support the entire operation of the machine.

- A camera (zoom, pan, rotated) attached to the machine support and in each relevant work area can be set from the operating station. The camera image is output via a separate monitor.

- A highly sensitive diagnostic system immediately detects faults, visualizes them and thus reduces downtimes and maintenance costs - for maximum machine availability. As an option, the customer‘s machine can be displayed three-dimensionally in order to localize the source of the fault as quickly as possible.