20% increased efficiency thanks to four boring mills

Investment pays off for Chinese market leader for mining machinery

In 2013, Xi’an Coal Mining Machinery Co., Ltd., one of China’s leading manufacturers of mining machinery, invested in four Union planer-type boring mills. The investment goal: to increase the efficiency and at the same time raise the machining quality of components in the production of shearers. Since the commissioning, the manufacturer of mining machinery looks back on a profitable investment.

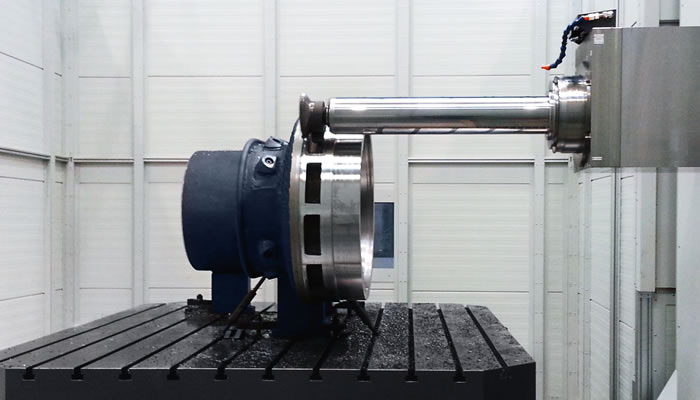

The completely enclosed boring and milling machines with a boring spindle diameter of 162 mm are generously dimensioned with between 3,200 and 4,000 mm traverse in the X-axis (workpiece table transverse direction) and 2,500 mm in the Y-axis (column vertical), and therefore perfectly suited for the complete machining of large, heavy workpieces. Machining shearer components requires particularly high machining precision. “The greatest challenge in machining these components is the concentricity of the bores,” says Mrs. Wang Xiaojing, Deputy Director of the technical committee of Xi’an Coal Mining Machinery. The stable design of the KCR with a strongly ribbed column, made of a single piece of cast iron, and excellent damping characteristics predestine the machines for high requirements in terms of precision.

Three parallel axes for higher precision

Specifically developed for precision machining, the Union K-Series has three parallel axes: V (column longitudinal), Z (ram) and W (boring spindle). Thanks to these, the machines meet even the tightest tolerances, as the column, ram and spindle movements overlap, which minimizes geometric inaccuracies. This results in absolutely stable cutting conditions beyond the middle of the table. As expected, the boring mill met the tolerances regarding geometric and positioning accuracy required by Xi’an Coal Mining Machinery to the customer’s full satisfaction when machining a test workpiece on the boring machines during the preliminary acceptance test.

Increased efficiency

Besides an increase in machining accuracy, Xi’an Coal Mining Machinery’s main investment goal was an optimization of machining times. In order to achieve maximum production efficiency and a reduction of downtime, the boring and milling machines are equipped with an automatic tool changer and some with a pick-up station for milling heads. Wang Xiaojing is satisfied with their long-term performance: „Thanks to the new machines, we were able to increase the overall efficiency of the production facility by approximately 20%.”

A sister company of Xi’an Coal Mining Machinery that is also based in Xi’an, Shaan’xi Construction Machinery, ordered two more machines, a KCR 150 with a spindle diameter of 150 mm and a table-type TC 130 with an automatic tool changer, as part of the same contract. The boring mills are used to manufacture machine components for road construction machinery. The deciding factor for the orders to be placed was the reliable adherence to the high precision requirements and tight tolerances and the on-site assistance: In WaldrichSiegen’s representative office in Beijing, an expert is available exclusively for customers interested in Union machines. Customers in China are supported by competent staff throughout the entire life cycle of the machine.