ProfiTurn V

Ultra-precision and performance lathes

ProfiTurn V at a glance

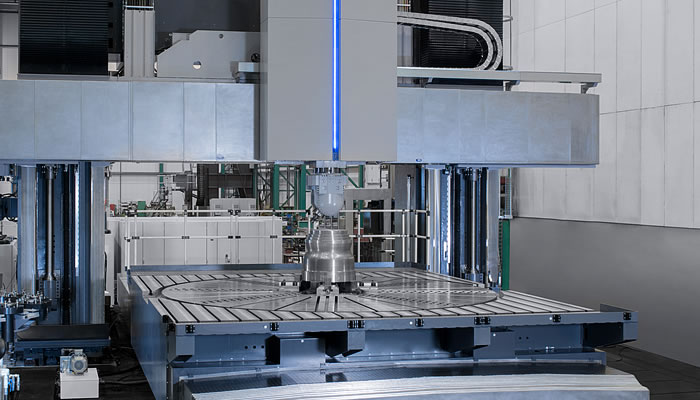

Based on our tradition and the experience gained in the many years of building horizontal lathes and portal milling machines, WaldrichSiegen now sets new benchmarks in the market with a new innovative machine concept. The vertical lathe, ProfiTurn V, excels in precision, efficiency and reliability. Characteristics WaldrichSiegen has been renowned for, for decades.

Unsurpassed in terms of precision and performance

Unique characteristics which make the ProfiTurn V lathe clearly stand out from other concepts currently available in the market are a significant increase in precision and performance provided by this innovative vertical lathe concept. The possibility to integrate a variety of technologies allows for highly flexible machining of complex workpieces. The fully hydrostatic design in all main axes guarantees ultimate cutting performance and accuracy.

Furthermore, the ProfiTurn V excels in terms of energy efficiency and ease of maintenance. In conjunction with fact that all machine components are of high quality "Made in Germany", these vertical lathes guarantee high productivity and minimized life-cycle cost.

Machine concept

The clear-cut, modular structure of the WaldrichSiegen ProfiTurn V series covers a wide range of machine configurations for machining a broad spectrum of workpieces. To ensure long-term reliability and superior quality, all major ProfiTurn V structural components are made of high-quality cast iron and are machined in-house at the highest precision.

Perfect solution for every task

Down to the last detail, the vertical lathes are designed for providing the perfect solution for any given machining task. The fully hydrostatic main axes of the machine ensure maximum static and dynamic stiffness, unsurpassed damping characteristics, zero backlash and a prolonged lifetime of the guideways. The hydrostatically guided rotary table allows for high table loads. All main axes of the ProfiTurn V – including the W-axis – are CNC controlled.

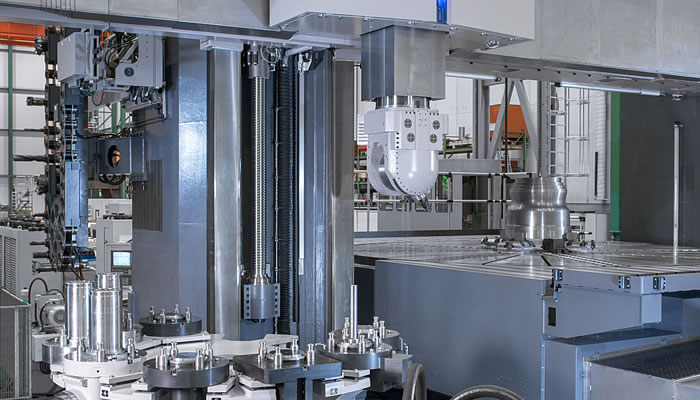

A wide range of attachments for turning, milling, boring and grinding operations are available for the ProfiTurn V. For the fully automatic exchange of attachments we offer different types of tool changers – from chain disk or rack-type tool changers to a tool arena with an integrated robot.

According to customer requirements, the ProfiTurn V can be equipped with a fixed rotary table, a rotary table with longitudinal displacement or with a portal in gantry design.

Technology

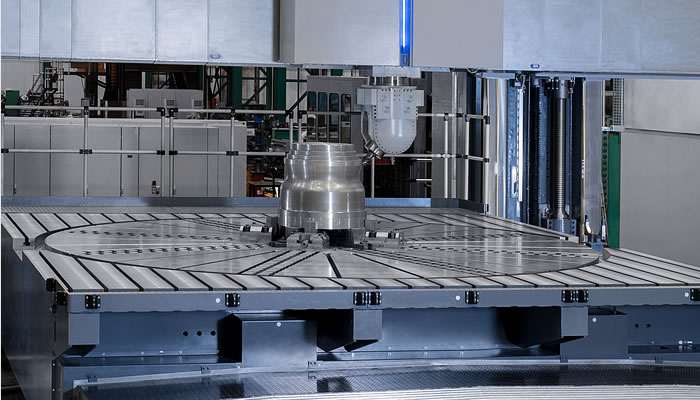

+ Rotary table

The base and faceplate of the rotary table are made of high-quality cast iron. The hydrostatically guided faceplate is equipped with a well-dimensioned main bearing and is driven by a zero backlash 2-step Master-slave drive. Further convincing design features of the ProfiTurn V are the machines' excellent static and dynamic properties, their extremely high driving torque and their high positioning accuracy during milling operations.

+ Masterhead concept

Taking into consideration the special requirements of vertical turning, the proven WaldrichSiegen Masterhead concept was translated and implemented in the ProfiTurn V machines. The Masterhead concept offers a lot of advantages, among others, high rigidity of the Masterhead interface, long lifetime of drive shaft bearings, low noise level along with excellent overall efficiency and maximum availability of the machine, to name only a few.

+ Tool changer

Fast and reliable exchange of a variety of different grinding, turning, milling and boring tools is a decisive factor for the economic and efficient manufacture of complex workpieces. Depending on space availability and the number of tools required, WaldrichSiegen provides different tool changing systems which guarantee minimum chip-to-chip times. According to individual customer requirements, we offer pick-up, disk-type, chain-type, rack-type tool changers or a tool arena with integrated roboter.

+ Tool management

State-of-the-art tool management systems considerably add to reducing machine downtimes. Independent of the machine control, the WaldrichSiegen Tool Management System manages all relevant technical data and information. Furthermore, the system can be interfaced with a company's production planning system and thus be efficiently integrated into the overall production process.

Options

For the ProfiTurn V, WaldrichSiegen offers a wide range of optional attachments for turning, milling, boring and grinding applications. All units feature a well-balanced speed/torque ratio. Based on the many years of experience WaldrichSiegen has gained in manufacturing lathes and milling machines, we also offer attachments in special design, tailor-made to the individual machining tasks of our customers.

The attachments of the ProfiTurn V series machines excel in:

- Maximum precision

- Long service life

- Grease lubricated bearings

- Interfaces for all common tool systems

Performance data

The ProfiTurn V vertical lathes stand for precision, reliability and performance. With its modular structure, the ProfiTurnV series offers a wide range of solutions for machining a broad spectrum of workpieces.

The main technical data of the ProfiTurn V machines at a glance:

- Turning diameter: up to 13,000 mm

- Turning height: up to 11,000 mm

- Ram travel: up to 4,000 mm

- Ram cross section: up to 600 x 600 mm

- High-performance main drives integrated into the ram for milling, boring and grinding operations

- Rotary table power: up to 300 kW

- Rotary table torque: up to 560,000 Nm

- Table load: up to 500 t

For machine dimensions beyond the scope of our modular machine program, we offer machines in special designs upon request.

ProfiTurn V