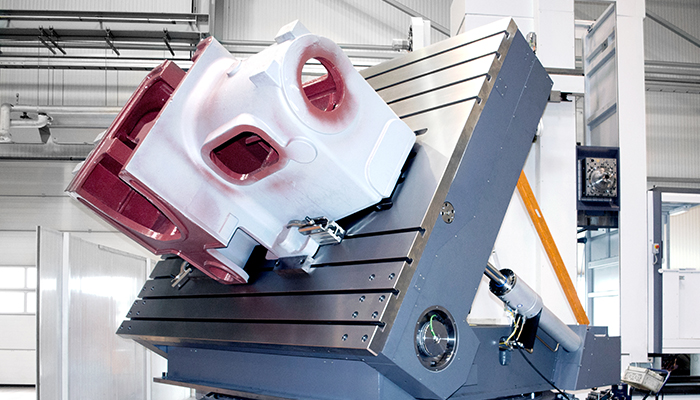

PR II 180 with special table design for manufacturing of wind mill hubs

For our Polish customer PPU Metalmor, a contract manufacturer with focus on large-part production for ship building, energy and wind energy industry as well as gearbox production, WaldrichSiegen produced a PR II 180 horizontal boring and milling machine with a special table design.

For the machining of wind mill rotor hubs, the customer needs a special table that not only rotates and moves horizontal but is also tiltable. The rotor hub connects the rotor blades with the generator and transmits the power to the rotor shaft. To process its inclined surfaces, the workpiece has to be tilted towards the tool up to 15°.

The PR II 180 is equipped with a Siemens control and full hydrostatic guideways. The overall dimensions of the machine as well as the travel of 8,000 mm in the X-axis, 4,500 mm in the Y-axis and 1,100 mm in the Z-axis allow a flexible manufacturing of workpieces up to 40 metric tons weight on the table or two additional floor plates. The boring spindle itself has a travel of 750 mm and a diameter of 180 mm.

For higher grade of automation, the boring mill is equipped with a tool changer for 40 tools and three milling heads. Besides an older T 130/1, the PR II is already the second boring mill for Metalmor.