Foundation-free compact boring mill TM 125

Flexible and compact at the same time

The Union TM 125 is the world’s first compact boring mill using the patented Monolith™-technology. Thanks to this expansion, WaldrichSiegen advances its broad product portfolio in the field of compact boring mills and differentiates itself from the competition by two unique features: The foundation-free Monolith™ machine bed and the boring spindle. The machine bed is made out of a special damping concrete, which enables an uncomplicated and easy installation directly on the factory floor as with a compact machining center. Thanks to the construction with side stand and boring spindle (quill), the machine convinces with bigger travel ranges as you have it with a boring mill.

Especially with smaller manufacturing companies, there are always new challenges regarding rapid reaction times on fast-changing market requirements. Often its uncertain which broad spectrum of working pieces have to be processed regarding the number, size and precision. To be prepared for every demand, investments in a boring mill seems to be the ideal solution compared to compact machining center, because of its higher flexibility. In practice, however, the costs and effort to install a boring mill is not always manageable, especially for the smaller companies due to the lack of space or infrastructure. With the TM 125, all of these considerations are history.

The best of both worlds

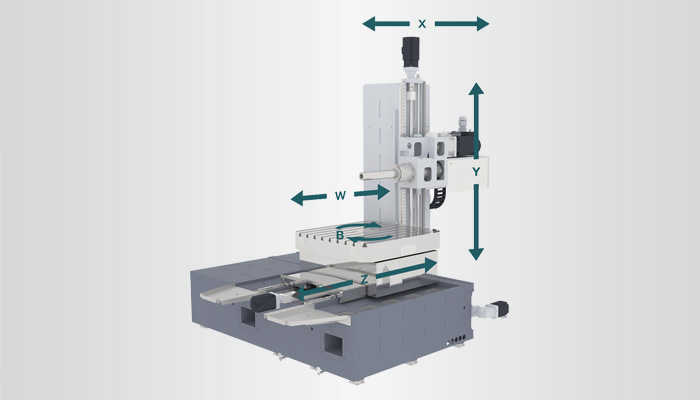

The TM 125 combines the advantages of a classic boring mill with table-top construction with the characteristics of a compact machining center. With a boring spindle of 125 mm, medium-duty working pieces with a total weight of 10 t and a travel of 2,500 x 2,000 x 1,600 mm can be processed cost-effective and efficiently. Based on the classic table-top construction of the Union T-series, the TM 125 convinces with big travel ranges, precise processing and accessibility and a high load capacity of up to 10 t. Tool changer, milling heads and table units, manufactured in-house by the HerkulesGroup, the TM 125 is as productive as a machining center.

On the other hand, the TM 125 doesn’t need a foundation, and can directly be installed on the hall floor – for easy mounting and faster repositioning of the machine thanks to the patented Monolith™-technology. This proven technology is used for roll grinding machines since 2001: The machine bed is torsionally rigid and thermostable. Its sandwich construction consists of an iron-cast, ribbed upper section, fiber-reinforced high-performance concrete and a steel floor panel with special damping elements. As there is no metal connection between the upper and lower section, vibrations are effectively damped. Another advantage: less floor space required.

This new compact machine was developed for the processing of prototype construction and the manufacturing of small, medium and large workpiece series. Additional flexibility can be achieved by optionally implemented equipment like lateral milling heads for five-axis processing or the Capto interface, which, in combination with a fast turning table, even allows lathe machining. “The TM 125 is the ideal compact boring mill for every average and high-precision machining task.”, Thorsten Mehlhorn, member of the management, explains. “With this machine, our customers are prepared for every workpiece range.”