ProfiGrind

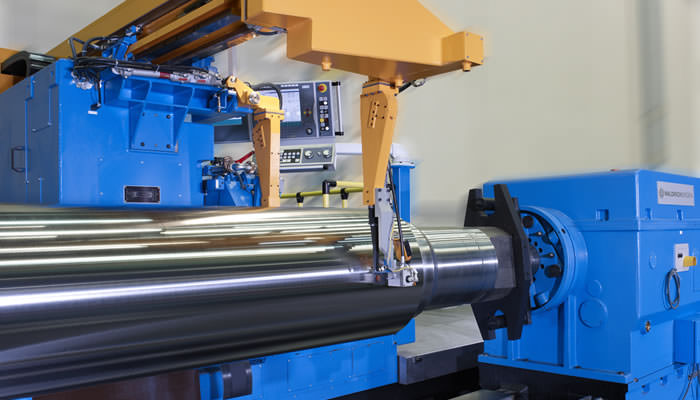

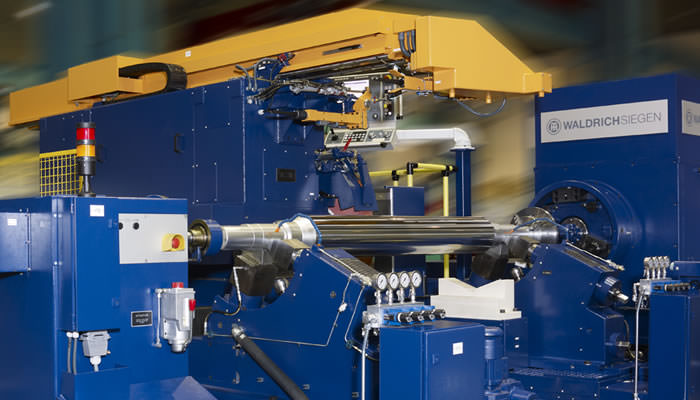

Cutting-edge technology: WaldrichSiegen roll grinders

The advantages at a glance

Precision, performance, reliability – these are the strong points of the ProfiGrind machines, appreciated by WaldrichSiegen customers all over the world. Taking into account changing market conditions and requirements, we have constantly further developed our products and have become technology leader. To date, more than 1,600 roll grinding and texturing machines from WaldrichSiegen are being operated in roll shops worldwide.

Consistent focus on precision and reliability

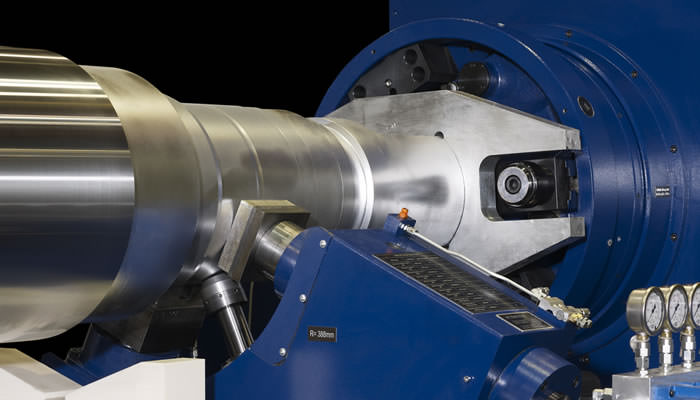

The roll grinders of the WaldrichSiegen ProfiGrind series are renowned for their very rigid design. All structural components are made of cast iron and machined in-house at tolerances within the micrometer range to ensure an extremely long lifetime, maximum reliability, stability and excellent damping characteristics.

The consistent integration of hydrostatic guideways provide for an almost wear-free operation, zero backlash, unsurpassed damping characteristics and high stock removal performance, excellent thermal characteristics and maximum precision.

Flexibility and versatility due to modular machine concept

With its modular structure, the WaldrichSiegen ProfiGrind series offers a perfect solution for every requirement and all demands.

Technology tailored to your needs

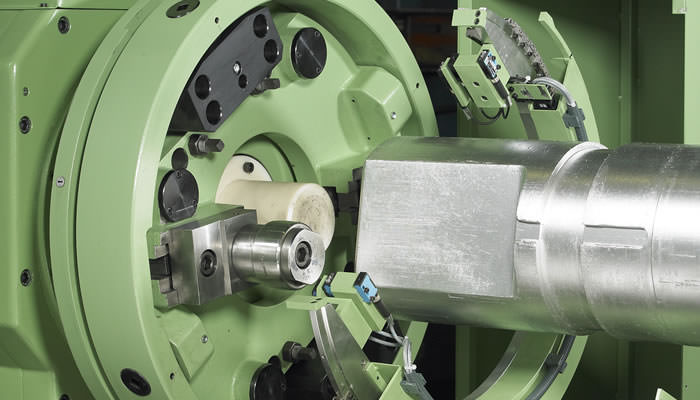

+ Upper and lower carriage

The WaldrichSiegen X-axis design is industry advancement in terms of stiffness and accuracy. The grinding spindle with hydrostatic U-axis provides for wear-free operation throughout the complete speed range and guarantees the highest precision. For grinding of specific roll curves with a large variety of diameters, WaldrichSiegen has developed the B-axis. This patented concept ensures that the grinding wheel is always positioned vertically to the corresponding tangent of a curve. Thus, infeed marks are eliminated. The cast iron upper carriage of the ProfiGrind machines is designed for maximum firmness. The wear-free Master-slave drive of the Z-axis prevents tilting at the reverse point of the grinding wheel and guarantees the highest long-term precision.

+ Headstock

The headstock housing of the ProfiGrind machines is designed for maximum stiffness. It is made of cast iron and is ribbed to yet further increase the firmness. Premium-quality bearings and components ensure the highest machining accuracy.

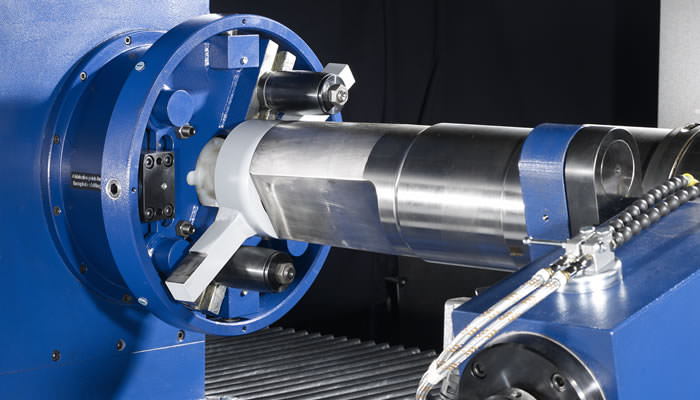

+ Tailstock

The tailstock housing, a closed construction made of ribbed cast iron, in conjunction with the generously dimensioned roller bearings ensure excellent run-out accuracies. The tailstock quill is exactly positioned via motor-driven operation and therefore allows for an exact pressure adjustment. Spring cups ensure a constant and safe load accommodation throughout the machining process. WaldrichSiegen optionally equips the tailstock with hydrostatic bearings.

+ Steady rests

Also in terms of steady rest design, WaldrichSiegen offers customized solutions geared to specific customer requirements:

- Hydrostatic steady rests

- Hydrodynamic steady rests

- Combined steady rests (hydrostatic and hydrodynamic)

+ Machine beds

The machine beds feature maximum bending and torsional stiffness and optimal load introduction into the foundation. In addition, precise and wear-free guidance of the lower carriage, as well as, exact positioning of the steady rests, tailstock and peripheral equipment is guaranteed.

+ Hydrostatic guideways and drives

Hydrostatic guideways and Master-slave drives are synonyms for dynamic stiffness and excellent damping characteristics of all carriage side components. The Master-slave concept for longitudinal drive and the ball screw for cross-adjustment guarantee the highest positioning accuracy.

+ Control

The PGC10 control has been developed specifically for roll grinding within the HerkulesGroup. It is the most powerful and versatile control in the market. All control and – optionally – measuring functions are integrated in the control and performed automatically. Usability was a major focus during development. The clearly structured user interface shows the most important data and the current grinding process at the first glance. A touch screen allows for uncomplicated use. The control runs on a Windows 10 IoT 64-Bit operating system and a PLC based on Beckhoff TwinCAT 3.1.

+ Roll measurement

The measuring system provides the geometrical data of the rolls that are necessary for the control of the roll machining process. It measures the roll with great precision, using 360 values per revolution. Measuring takes place both before and during the grinding process. If the roll rotates slowly, an average value is formed from the raw data, which accrue at a high temporal resolution of 1 ms. This averaging improves the quality of the measured data yet again. The measuring beam is mounted at the lower carriage and equipped with two measuring calipers.

Options

+ Ultrasound and eddy current technology

Roll spalling is often the reason for serious interruptions of operation in rolling mills that result in considerable downtime and consequential damage. In order to prevent these, crack detection devices can be integrated in the roll grinder. Ultrasonic and eddy current systems reliably identify and localize cracks, structural changes and defects at the roll surface before the roll is put to use in the roll rack. After measuring, the results are displayed exactly and clearly structured. Ultrasonic and eddy current measuring devices are either available as independent systems or they can be integrated in the machine control.

+ Surface inspection

The Roll Surface Inspection System (RSIS) ensures the quality of the roll surface after the grinding process. Visual surface defects such as chatter and infeed marks are detected reliably and automatically. A laser beam is directed at the rotating roll. The reflection of the beam is recorded by sensors and then evaluated – thus creating an image of the entire roll barrel. The evaluation of the surface quality and the operability of the roll is based on preset threshold values. A simple traffic light system informs the machine staff whether the roll meets the defined quality standards.

+ Automatic loading and unloading systems

In terms of roll handling, automated roll shops provide for considerable time savings. The automatic WaldrichSiegen roll loading/unloading system minimizes the need for manual intervention and is also suited for the handling of hot strip work rolls in chocks. Functions and tasks of a chock rotating/swiveling device can be carried out by the automatic loading/unloading system.

+ Automation

Automatic roll shops save a lot of time in terms of roll handling, for example with the help of an automatic loader by WaldrichSiegen. It can also load hot mill work rolls with chocks and take over the tasks of the chock tilting device.

Further options for the automation comprise the automatic detection of the roll necks to couple the roll with the headstock, additional measuring, and corrosion protection devices that automatically dry and grease the rolls.

Performance data

WaldrichSiegen roll grinders feature cutting-edge technology and excel in precision, performance, reliability and long service life. With a focus on individual customer orientation, the machines offer a high degree of flexibility:

- Grinding wheel power: up to 500 kW

- Workpiece weight: up to 300 t

- Workpiece length: up to 21,000 mm

- Workpiece diameter: up to 2,500 mm

- Concentricity of 1 µm