ProfiTurn H Turning

Horizontal lathes for highest precision and performance

ProfiTurn H at a glance

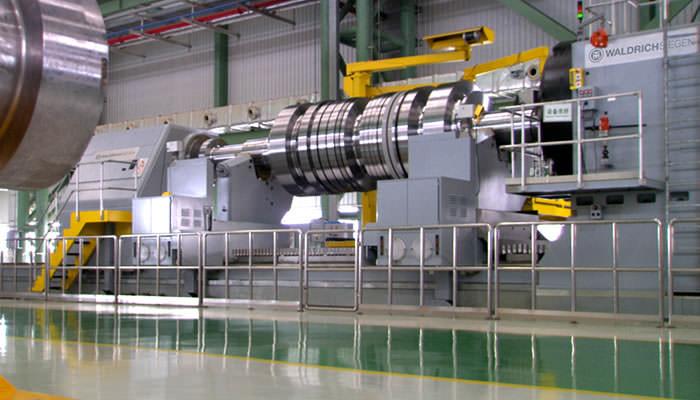

WaldrichSiegen horizontal turning lathes, ProfiTurn H, provide the highest accuracies, reliability and performance, allowing for high quality and economic machining of complex workpieces. Great importance is attached to a rugged design and maximum stiffness of the overall machine structure. In principle the ProfiTurn H series is equipped with hydrostatic guideways in all linear axes providing for high, wear-free operation along with excellent damping characteristics.

All major components are manufactured in-house with the highest precision. Our wide range of options, developed to reduce reclamping, alignment and machining times considerably, provides maximum flexibility.

Given its high energy efficiency, easy maintenance and "Made in Germany" quality of all components, ProfiTurn H impresses with the high productivity and availability resulting in low life cycle costs.

Concept

Guaranteed precision in all applications

Maximum stiffness of the overall machine structure is crucial for achieving highly precise machining results. Therefore, ProfiTurn H lathes are of very rugged design. All major components are made of high-quality cast iron and manufactured in-house at the highest tolerances in order to guarantee the accuracies, reliability and long lifetime WaldrichSiegen machines are known for.

By consequently integrating hydrostatical guide ways WaldrichSiegen gives you significant advantages: elimination of friction, wear-free and zero-backlash guide ways as well as best damping characteristics even during heavy cutting.

We offer:

- Machines in one and two carriage design

- Integration of additional technologies like milling, turn-milling, grinding, drilling, measuring

- Different combinations of tool carriers

- Tool change / change of various attachments

Machine technology individually tailored to your requirements

+ Machine beds

WaldrichSiegen machine beds – made of cast iron – are available in one-section or two-section design. Their ribbed structure ensures maximum bending and torsional stiffness, as well as, an optimal load introduction into the foundation. Precise guidance of the bed slide and exact positioning of steadies, tailstock and peripheral equipment are completely guaranteed as well.

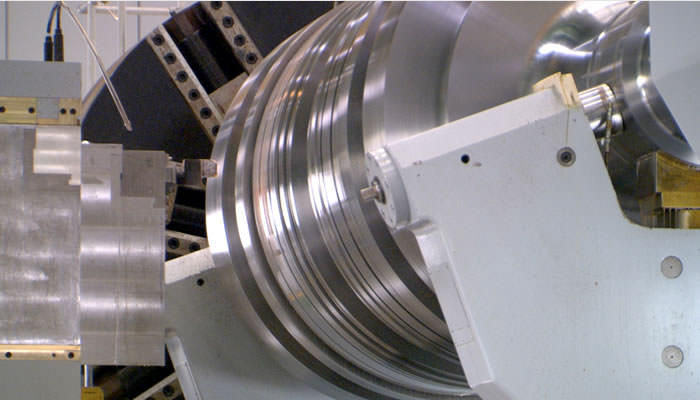

+ Headstock and faceplate

The headstock design is crucial for the achievement of the highest run-out accuracies and maximum performance. Therefore, it is cast in one piece and additionally ribbed. The axial and radial bearing placed close to the faceplate provides for the highest precision. Made of cast iron, as well, the faceplate can accommodate workpiece weights of up to 500 tons. State of the art drive systems like the Master-Slave-drive, for example, enable the optimal machining of workpieces with the highest precision and performance.

+ Hydrostatic guideways and drives

Either a hydrostatic worm or an electrically pre-loaded Master-Slave double drive is used for longitudinal drive. Traverse adjustment of the upper carriage is carried out via a pre-loaded ballscrew. With the extremely high dynamic stiffness of the hydrostatic worms which allows for heavy duty cutting machines, WaldrichSiegen sets new standards in the market.

+ Upper carriage with tool carriers

WaldrichSiegen turning lathes meet the requirements for the highest stiffness and accuracy by means of an optimized upper carriage made of cast iron which can be adapted to the respective machining tasks. A suitable combination of tool carriers in different widths allows the machine to be adjusted for each customer's request.

+ Tailstock and counterstay

Even the tailstock is a closed one-piece construction made of ribbed cast iron. Well-dimensioned anti-friction bearings accommodate the center shaft resp. the quill in order to achieve excellent run-out accuracies. The tailstock systems are designed for workpiece weights of up to 500 tons.

+ Steady rests

Our solutions range from simple, manually adjustable roller steadies for applications in forges, to complex numerically controlled combination steadies for high-precision tasks, as for example, the machining of rotors.

+ Control technology

Latest state-of-the-art control technology made by well-known manufacturers ensures maximum reliability and user friendliness. The integrated diagnostic system, developed by WaldrichSiegen, monitors all relevant machine parameters, thus keeping the machine operators permanently informed on the current machine status and helping them in troubleshooting as to reduce downtime to a minimum.

Options

ProfiTurn H machines are optionally equipped with a large number of process-optimizing solutions in order to further reduce machining times of complex workpieces and achieve the highest machining quality.

+ Pivoting tool holder

The use of a pivoting tool holder for turning mould cavities into generator rotors significantly simplifies the procedure and even provides for a maximum degree of automation. As a result, process stability is increased and machining times are considerably reduced.

+ Dual cutting device

The Dual cutting device – an attachment with numerically adjustable tool carriers – allows for simultaneous and precise machining of symmetric turbine rotor disks with fir tree profiles.

+ Box-type toolholder

The Box-type tool holder allows for presetting a number of tools prior to the machining process which can later be loaded semi-automatically into the upper carriage. Thus, groove patterns can be finish-machined in one single cut.

Performance data

Our ProfiTurn H horizontal lathes have been developed to offer maximum performance for each application.

In more precise terms, this means:

- Power of up to 500 kW

- Torques of up to 400,000 Nm

- Workpiece weights of up to 500 tons

- Workpiece lengths of up to 30,000 mm

- Workpiece diameters of up to 7,000 mm

- Concentricity of ≥ 5 µm

ProfiTurn H Turning